HIMAX TL SERIES TECH. DATA

All the distinguishing features of the HIMAX Electric Screwdriver that no one can beat

Full range of models with the range of the torque 0.2Kg-cm~20.0Kg-cm and with variable adjustment.

High precision torque control device with the torque precision ± 3% and no reactionary force and without slipping.

Brand new ergonomic design, work long hours without fatigue, increase productivity

Low-voltage DC motor driven, extremely safe during operation and noise-free

Precise and simplified internal structure, maintenance free, durable, and long life

Supplies and carbon rods can be replaced directly from the external.

The screwdriver body is separated from the power supply to simplify the maintenance

Simple and easy to add accessories to fit all types of work

Based on the self-confidence and the guarantee of the quality, we provide after-sale services for one year free and professional after-sale services thereafter

The technologies of the HIMAX Electric Screwdriver

Stability

Use two sets of ball bearing for the orientation of the transmission system to achieve stability in the output of the rotational transmission torque

Accuracy

Use all-alloy steel gears and an all-in-one design of gear box and the inner tooth, compact, high precision, and matching with a unique planet carrier plate transmission axle, forming one body and polished by grinding to become high-rigidity, high operability, and low frictional forces and can endure long-term use without the reduction of precision.

Durability

Unique planet carrier plate transmission axle, forming one body and polished by grinding to become high-rigidity, high operability, and low frictional forces and high long-term use life time.

Lightweight

Lightweight all-aluminum alloy casing, anode harden treatment through the whole process, improve the environmental tolerance and the corrosion resistance ability. The gears are made of V-Cr-Mo alloy steel , hardened first and then treated with the unique, state of the art, plasma nitride equipment to gain the best wear resistance and toughness.

High efficiency

A precision balanced design for motor and gear group, all-in-one structure design of the planet carrier shaft and the output axial the structure, and the output shaft axis Configuration for mining large span designed to ensure that the most rigid and reverse output capacity.

Low temperature

Use ultra-powerful (NdFeB) Neodymium Iron boron magnets so that the motor will cool quickly. As a result, the screwdriver can operate continuously and keep the temperature low for a long time.

Low failure rate

Use the OMRON brake triggered switch and start-up switch, low failure rate .

The superiority of the HIMAX Electric Screwdriver

Excellent quality: patented clutch control, simplified structure to achieve zero defect

Reasonable price: 25% cheaper than Japanese imports.

Full product Certification: Certified fully by the CCC System

Easy maintenance: local service centers with plenty of spare parts

Product Warranty: One year of original factory warranty to assure quality

Ergonomic design: elegant appearances, high operability

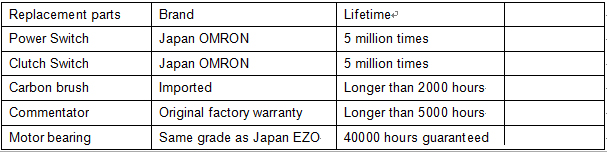

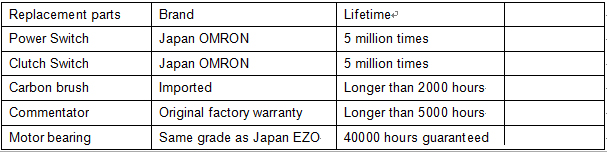

Replacement Parts warranty for the HIMAX Electric Screwdriver

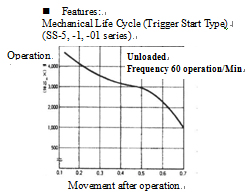

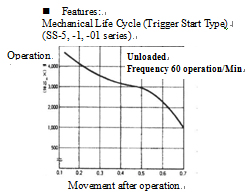

Clutch condition measurement standard for the HIMAX Electric Screwdriver HIMAX TL-5000 uses Japan OMRON SS-5 Clutch power switch

Operation speed: 0.1mm~lm/s

Frequency of action: mechanical 300 times/min

Contact resistance: Below 50mΩ

Vibration: 10~55Hz dual amplitude 1.0mm

Machine lifetime: Over 5 million times

OMRON SS-5 model mechanical lifetime curve(button type)

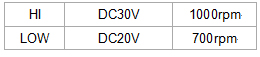

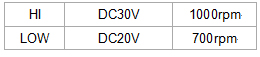

Rotation speed measurement standard/method for the HIMAX Electric Screwdriver

Sampling rate: 10%

For every HIMAX TL-5000 sample, depending on the output rotation range

After using a vise to fix the Electric Screwdriver, perform the measurement with a non-contact Photo Digital tachometer

Measurement time: After continuous operating for 3 min,. measure for 1 min.

Photo Digital projection distance: 3cm

Measurement position: connecting shaft to the screwdriver head

Measurement equipment used::Lutron Photo Digital Tachometer DT-2238

Resolution 0.1rpm(<1000rpm)/1rpm(>1000rpm)

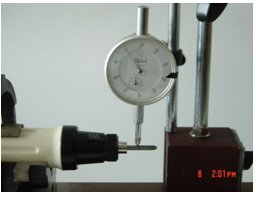

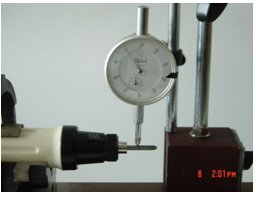

Eccentric displacement measurement standard/method for the HIMAX Electric Screwdriver

Sampling rate: 10%

After using a vise to fix the Electric Screwdriver, perform the measurement with an eccentric scale

After continuous operating for 3 min, measure for 30sec..

Measurement position: connecting shaft to the screwdriver head

Measurement equipment used:: Teclock Dial Gauge TM-110

Measurement standard: within ±0.1mm Eccentric displacement

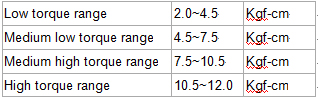

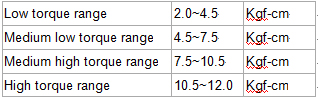

Torque measurement standard/method for the HIMAX Electric Screwdriver

Sampling rate: 10%

For every HIMAX TL-5000 sample, depending on the output torque distribution range 2.0-12.0Kgf-cm

Perform 4 stage measurement

Perform 50 measurements respectively and the average measurement value X should be within ±3% of the accuracy range

Measurement equipment used: Japan HIOS Torque Meter HP-100

Equipment calibration by::I PAO ELECTRONICS CO LTD .

Certificate number: 2125P212

Japan Mitutoyo Digimatic Microprosser Model No. Dp-1hs

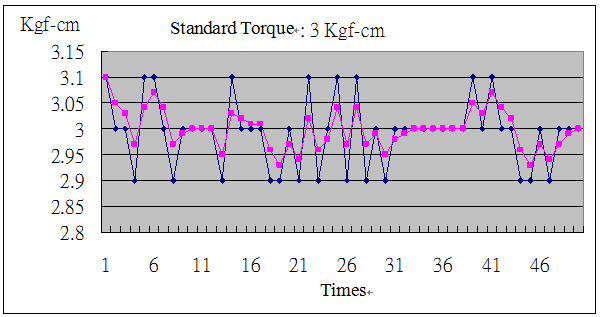

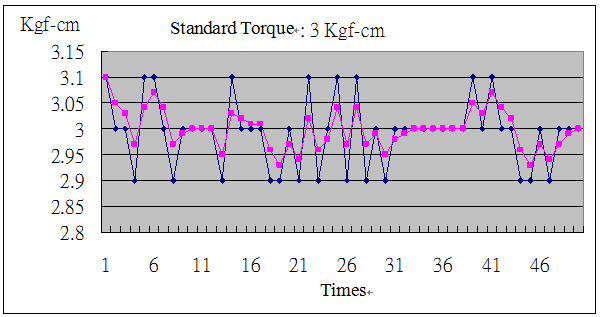

Fig. 1: Torque setting :3.0Kgf-cm

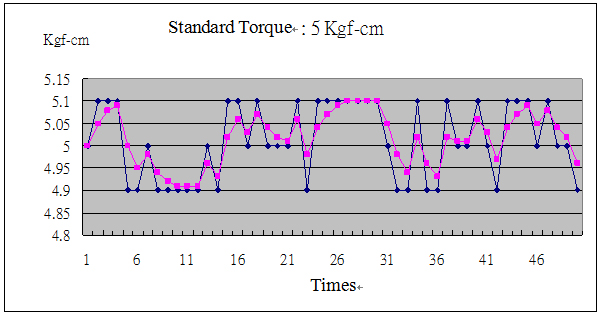

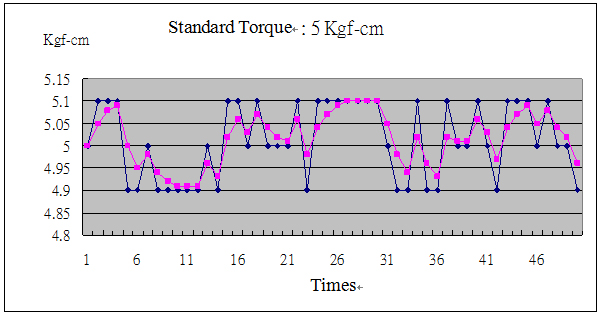

Fig. 2: Torque setting :5.0Kgf-cm

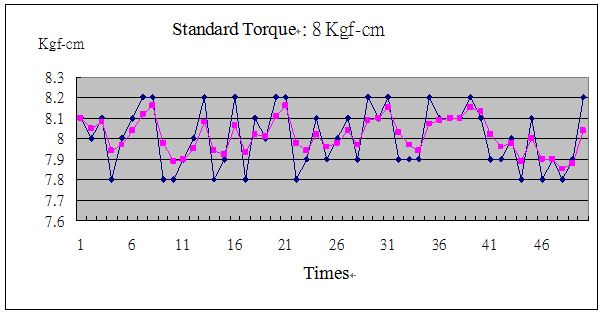

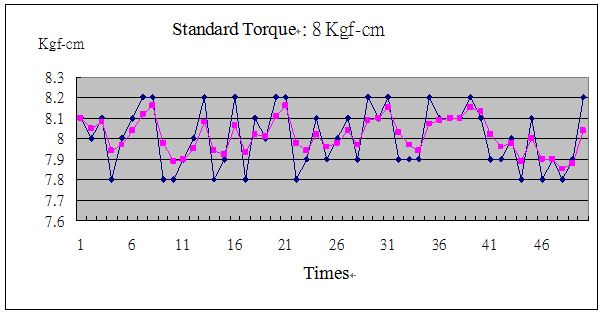

Fig. 3: Torque setting :8.0Kgf-cm

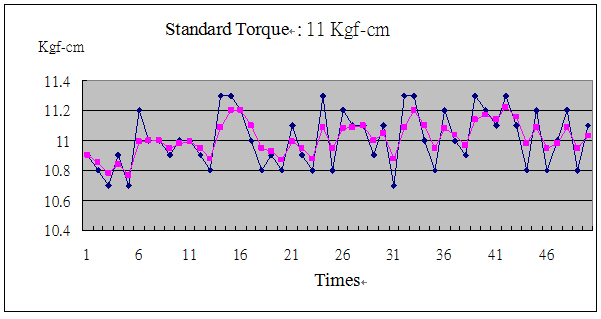

Fig. 4: Torque setting :11.0Kgf-cm

Fig.1

Times of measurement: 50 times

Upper limit value:3.1Kgf-cm

Lower limit value:2.9 Kgf-cm

Average value:2.99 Kgf-cm

Blue points: measured value, Red points : averaged value

Fig.2

Times of measurement: 50 times

Upper limit value:5.1Kgf-cm

Lower limit value:4.9 Kgf-cm

Average value:4.96 Kgf-cm

Blue points: measured value, Red points : averaged value

Fig.3

Times of measurement: 50 times

Upper limit value:8.2Kgf-cm

Lower limit value:7.8 Kgf-cm

Average value:8.04 Kgf-cm

Blue points: measured value, Red points : averaged value

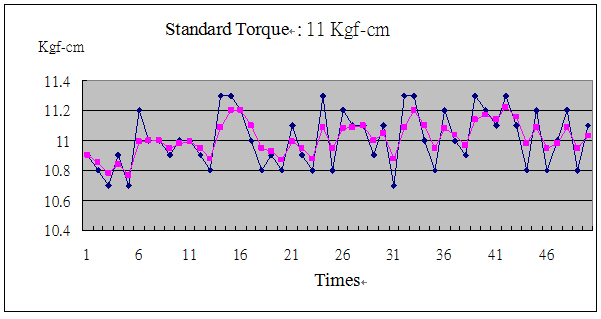

Fig.4

Times of measurement: 50 times

Upper limit value:11.3Kgf-cm

Lower limit value:10.7 Kgf-cm

Average value:11.03 Kgf-cm

Blue points: measured value, Red points : averaged value

Full range of models with the range of the torque 0.2Kg-cm~20.0Kg-cm and with variable adjustment.

High precision torque control device with the torque precision ± 3% and no reactionary force and without slipping.

Brand new ergonomic design, work long hours without fatigue, increase productivity

Low-voltage DC motor driven, extremely safe during operation and noise-free

Precise and simplified internal structure, maintenance free, durable, and long life

Supplies and carbon rods can be replaced directly from the external.

The screwdriver body is separated from the power supply to simplify the maintenance

Simple and easy to add accessories to fit all types of work

Based on the self-confidence and the guarantee of the quality, we provide after-sale services for one year free and professional after-sale services thereafter

The technologies of the HIMAX Electric Screwdriver

Stability

Use two sets of ball bearing for the orientation of the transmission system to achieve stability in the output of the rotational transmission torque

Accuracy

Use all-alloy steel gears and an all-in-one design of gear box and the inner tooth, compact, high precision, and matching with a unique planet carrier plate transmission axle, forming one body and polished by grinding to become high-rigidity, high operability, and low frictional forces and can endure long-term use without the reduction of precision.

Durability

Unique planet carrier plate transmission axle, forming one body and polished by grinding to become high-rigidity, high operability, and low frictional forces and high long-term use life time.

Lightweight

Lightweight all-aluminum alloy casing, anode harden treatment through the whole process, improve the environmental tolerance and the corrosion resistance ability. The gears are made of V-Cr-Mo alloy steel , hardened first and then treated with the unique, state of the art, plasma nitride equipment to gain the best wear resistance and toughness.

High efficiency

A precision balanced design for motor and gear group, all-in-one structure design of the planet carrier shaft and the output axial the structure, and the output shaft axis Configuration for mining large span designed to ensure that the most rigid and reverse output capacity.

Low temperature

Use ultra-powerful (NdFeB) Neodymium Iron boron magnets so that the motor will cool quickly. As a result, the screwdriver can operate continuously and keep the temperature low for a long time.

Low failure rate

Use the OMRON brake triggered switch and start-up switch, low failure rate .

The superiority of the HIMAX Electric Screwdriver

Excellent quality: patented clutch control, simplified structure to achieve zero defect

Reasonable price: 25% cheaper than Japanese imports.

Full product Certification: Certified fully by the CCC System

Easy maintenance: local service centers with plenty of spare parts

Product Warranty: One year of original factory warranty to assure quality

Ergonomic design: elegant appearances, high operability

Replacement Parts warranty for the HIMAX Electric Screwdriver

Clutch condition measurement standard for the HIMAX Electric Screwdriver HIMAX TL-5000 uses Japan OMRON SS-5 Clutch power switch

Operation speed: 0.1mm~lm/s

Frequency of action: mechanical 300 times/min

Contact resistance: Below 50mΩ

Vibration: 10~55Hz dual amplitude 1.0mm

Machine lifetime: Over 5 million times

OMRON SS-5 model mechanical lifetime curve(button type)

Rotation speed measurement standard/method for the HIMAX Electric Screwdriver

Sampling rate: 10%

For every HIMAX TL-5000 sample, depending on the output rotation range

After using a vise to fix the Electric Screwdriver, perform the measurement with a non-contact Photo Digital tachometer

Measurement time: After continuous operating for 3 min,. measure for 1 min.

Photo Digital projection distance: 3cm

Measurement position: connecting shaft to the screwdriver head

Measurement equipment used::Lutron Photo Digital Tachometer DT-2238

Resolution 0.1rpm(<1000rpm)/1rpm(>1000rpm)

Eccentric displacement measurement standard/method for the HIMAX Electric Screwdriver

Sampling rate: 10%

After using a vise to fix the Electric Screwdriver, perform the measurement with an eccentric scale

After continuous operating for 3 min, measure for 30sec..

Measurement position: connecting shaft to the screwdriver head

Measurement equipment used:: Teclock Dial Gauge TM-110

Measurement standard: within ±0.1mm Eccentric displacement

Torque measurement standard/method for the HIMAX Electric Screwdriver

Sampling rate: 10%

For every HIMAX TL-5000 sample, depending on the output torque distribution range 2.0-12.0Kgf-cm

Perform 4 stage measurement

Perform 50 measurements respectively and the average measurement value X should be within ±3% of the accuracy range

Measurement equipment used: Japan HIOS Torque Meter HP-100

Equipment calibration by::I PAO ELECTRONICS CO LTD .

Certificate number: 2125P212

Japan Mitutoyo Digimatic Microprosser Model No. Dp-1hs

Fig. 1: Torque setting :3.0Kgf-cm

Fig. 2: Torque setting :5.0Kgf-cm

Fig. 3: Torque setting :8.0Kgf-cm

Fig. 4: Torque setting :11.0Kgf-cm

Fig.1

Times of measurement: 50 times

Upper limit value:3.1Kgf-cm

Lower limit value:2.9 Kgf-cm

Average value:2.99 Kgf-cm

Blue points: measured value, Red points : averaged value

Fig.2

Times of measurement: 50 times

Upper limit value:5.1Kgf-cm

Lower limit value:4.9 Kgf-cm

Average value:4.96 Kgf-cm

Blue points: measured value, Red points : averaged value

Fig.3

Times of measurement: 50 times

Upper limit value:8.2Kgf-cm

Lower limit value:7.8 Kgf-cm

Average value:8.04 Kgf-cm

Blue points: measured value, Red points : averaged value

Fig.4

Times of measurement: 50 times

Upper limit value:11.3Kgf-cm

Lower limit value:10.7 Kgf-cm

Average value:11.03 Kgf-cm

Blue points: measured value, Red points : averaged value